In today's modern manufacturing industry, cutting machines have become an essential tool for producing a wide range of products, from building materials and automotive components to electronic devices and household items. However, when it comes to selecting a cutting machine, the properties of the material being cut are often a key factor in the decision-making process. Different materials require different cutting machines to meet varying demands. We will discuss how to choose the right cutting machine based on the properties of the material being cut to achieve the best cutting results.

For materials with lower hardness, such as wood, plastic, and rubber, commonly used cutting machines include CNC routers and laser cutting machines. CNC routers use rotating cutting tools for engraving and cutting, and offer high precision, speed, and low cost. CNC routers are ideal for producing high-quality wooden furniture, models, signs, and other products that require high precision. However, when it comes to cutting complex shapes, laser cutting machines are usually more suitable. Laser cutting machines use laser beams for cutting, allowing them to easily handle complex cutting requirements with high precision, speed, and automation. Therefore, for products that require high precision cutting, such as models and art pieces, laser cutting machines are the better choice.

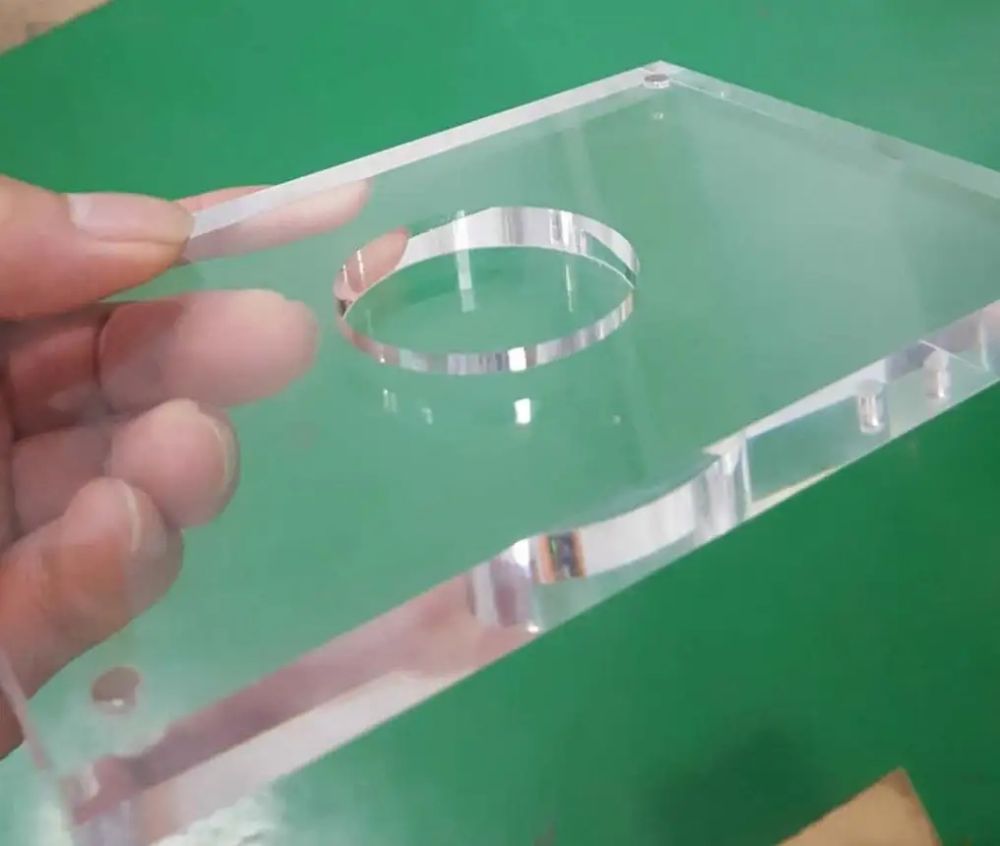

For materials with higher hardness, such as metal, glass, and ceramics, commonly used cutting machines include fiber laser cutting machines and plasma cutting machines. Plasma cutting machines use high-energy plasma for cutting, and are suitable for thick metal sheets and complex shapes, but are also more expensive. Fiber laser cutting machines, on the other hand, use high-energy laser beams for cutting and can handle high-precision, high-speed, and high-difficulty cutting requirements. Fiber laser cutting machines can cut a wide range of metals, such as steel, aluminum, brass, and copper, as well as hard non-metallic materials like glass and ceramics. They offer low cost, high precision, and are widely used in various applications.

In summary, selecting the right cutting machine requires consideration of the properties of the material being cut, as well as the specific cutting requirements. CNC routers are ideal for materials with lower hardness and products that require high precision cutting, while laser cutting machines are better suited for complex shapes. Fiber laser cutting machines are best for materials with higher hardness, including metals and hard non-metallic materials, and offer high precision and low cost.

If you don't know how to choose a suitable machine to cut engraving materials, you can contact us, and we will choose a suitable machine for you according to the material situation and application scenarios. Help you choose the cnc machine that suits your needs and ultimately achieve the best cutting results.

Post time: Mar-15-2023