Laser tube cutting machines have become increasingly popular in manufacturing, fabrication, and metalworking industries due to their accuracy, speed, and versatility. These machines use a high-powered laser beam to cut and shape various types of metal tubes, including stainless steel, aluminum, brass, and copper. We will explore the capabilities of laser tube cutting machines and the benefits they offer.

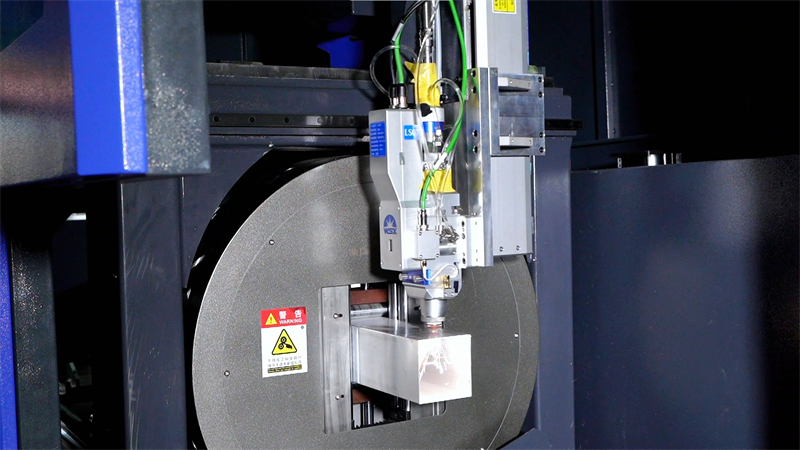

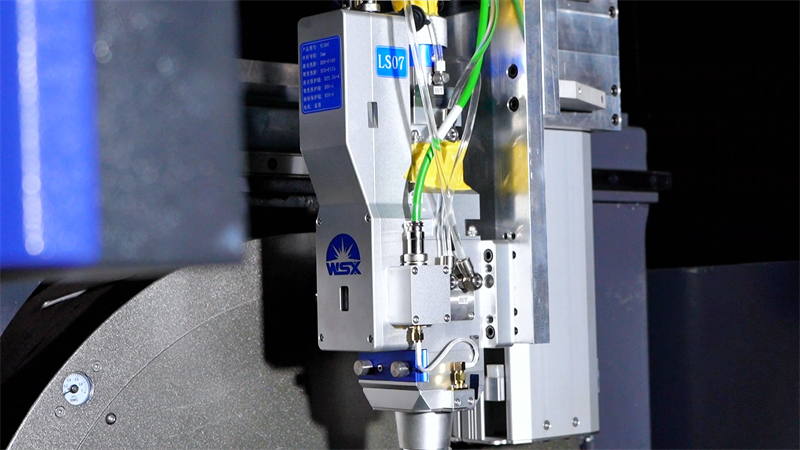

Laser tube cutting machines can produce precise and complex shapes with high accuracy and repeatability, which is not possible with traditional cutting methods such as sawing, drilling, or milling. The laser beam can cut through the metal tube without creating any burrs, sharp edges, or deformation, ensuring a clean and smooth finish. The cutting process is computer-controlled, which means the machine can produce identical parts in large quantities with minimal operator intervention.

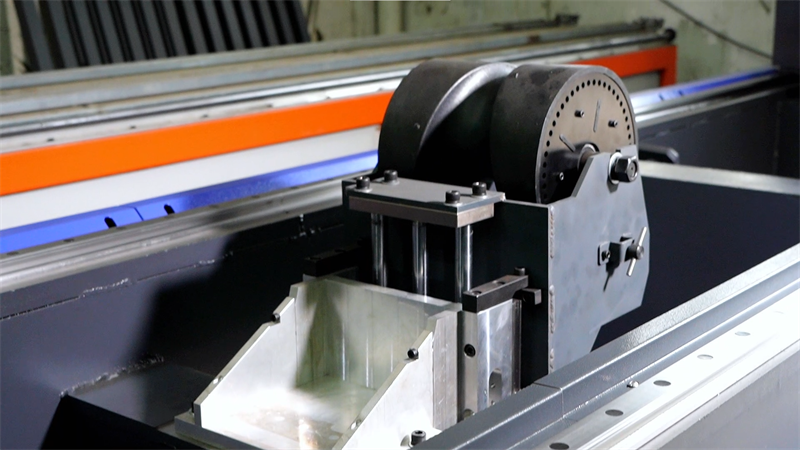

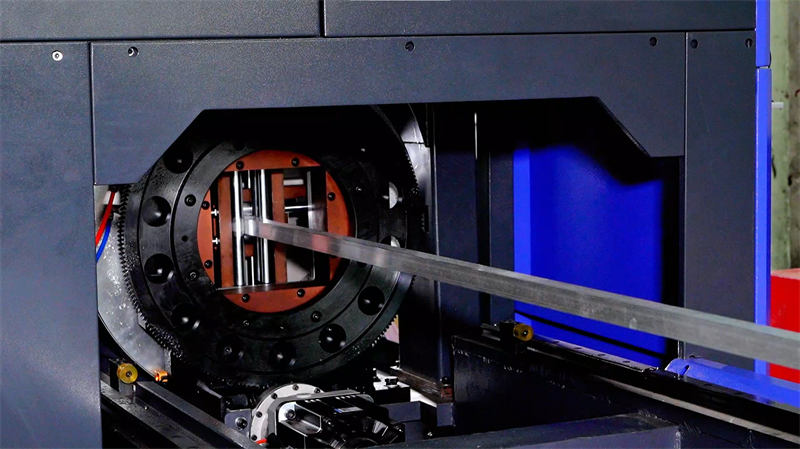

Laser tube cutting machines are also versatile and can handle a wide range of tube shapes and sizes. They can cut round, square, rectangular, and oval tubes with diameters ranging from a few millimeters to several inches. Some advanced machines can even cut bent and twisted tubes without any distortion, thanks to their 3D cutting capabilities.

Apart from cutting, laser tube cutting machines can also perform other tasks such as drilling, marking, and engraving on the tube's surface. This makes them a complete solution for metal fabrication, saving time and cost compared to using multiple machines.

The benefits of laser tube cutting machines include improved efficiency, reduced waste, and enhanced product quality. They can cut through thick metal tubes at high speeds, reducing production time and increasing throughput. They also minimize material waste by using the laser beam's precise cutting ability, which results in fewer scraps and lower material costs. The finished products are of high quality, with accurate dimensions, clean edges, and smooth surfaces, making them suitable for a wide range of applications.

In conclusion, laser tube cutting machines are a valuable asset for any metalworking business that requires precision, speed, and versatility. They can handle various tube shapes and sizes, perform multiple tasks, and offer significant benefits in terms of efficiency, waste reduction, and product quality. With their advanced features and capabilities, laser tube cutting machines have become a game-changer in the metalworking industry.

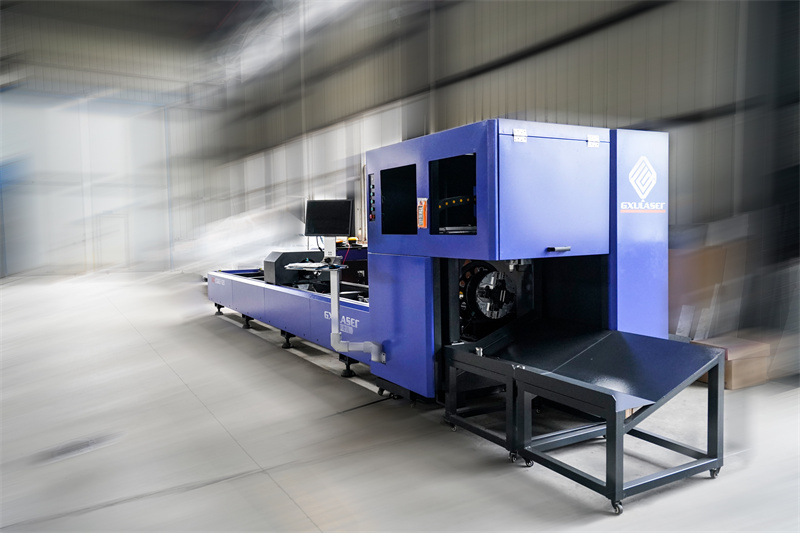

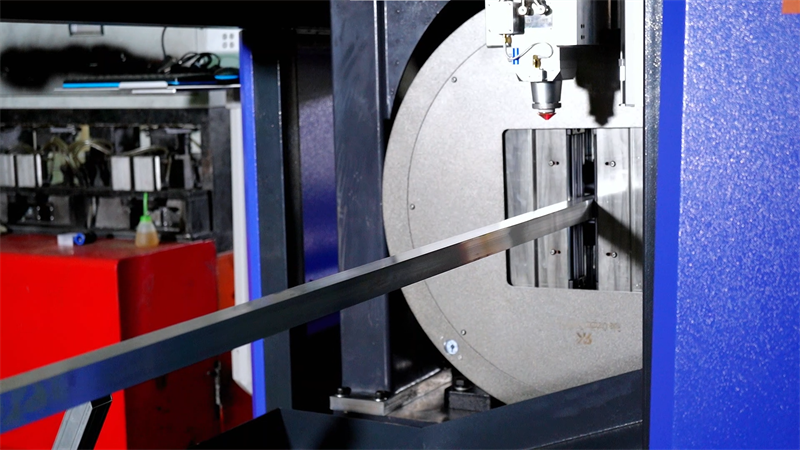

CG60 is a laser cutting machine developed by us, which perfectly meets all the needs of pipe cutting. Welcome to consult us for details.

Post time: Mar-29-2023