Overview

Condition:New

Range of Spindle Speed(r.p.m):1 - 24000 rpm

Positioning Accuracy (mm):0.01mm

Number of Axes:3

No. of Spindles:Single

Working Table Size(mm):1300×2500

Machine Type:CNC Router

Travel (X Axis)(mm):1300 mm

Travel (Y Axis)(mm):2500 mm

Repeatability (X/Y/Z) (mm):0.01 mm

Spindle Motor Power(kW):6

CNC or Not:CNC

Place of Origin:Zhejiang, China

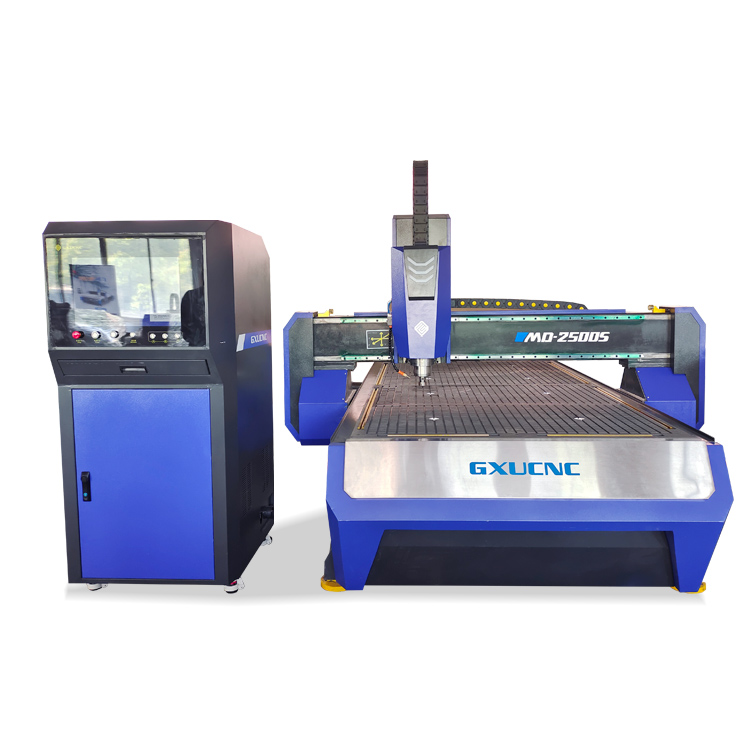

Brand Name:GXUCNC

Voltage:AC220/50Hz

Dimension(L*W*H):3.05m*2.1m*1.85m

Power (kW):6

Weight (KG):1800

Control System Brand:NC Studio, DSP, RichAuto

Warranty:2 years

Key Selling Points:High-accuracy

Applicable Industries:Printing Shops, Other, Advertising Company, Funiture manufacturing

Video outgoing-inspection:Provided

Warranty of core components:2 years

Core Components:Motor

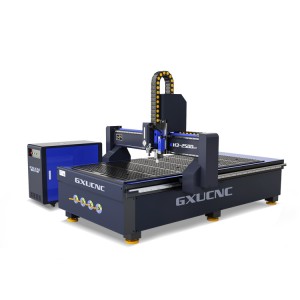

Product Name:CNC Wood Working Machine

Working area:1300MM*2500MM

Total spindle power:6.0KW

Processing precision:±0.05MM

Repeat Processing accuracy:±0.02MM

Running Speed:50m/min

Drive motor:servo motor

Power Supply:AC380V/50HZ

N.w:1800KG

Service provided:Online or go on-site

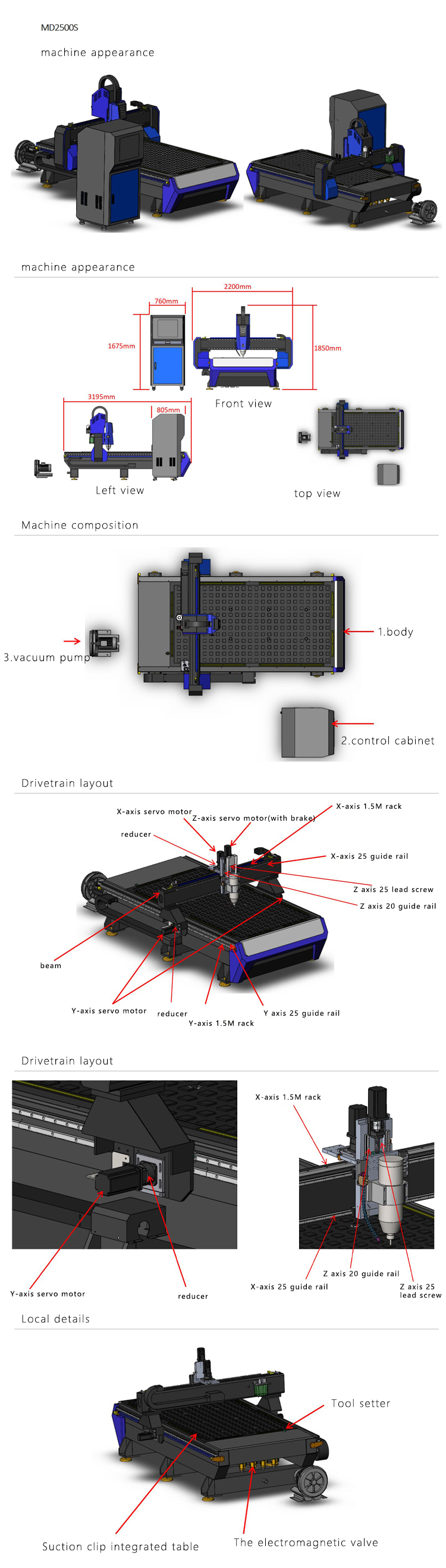

Machine datails

|

Working Area |

1.3×2.5 m |

Repeat position accuracy |

±0.01mm |

|

Total Spindle Power |

6Kw |

Drive motor |

Servo Motor |

|

Running Speed |

50m/Min |

Power Supply |

380v/50HZ |

|

Processing Accuracy |

±0.01mm |

N.W |

1700Kg |

Application areas

Suitable for aluminium, acrylic,wood, plastic, aluminous model board, Copper, and Carbon fiber composite materials, carving ,milling, cutting and whittling, widely used in soft metal and sheet metal processing.

Machine features

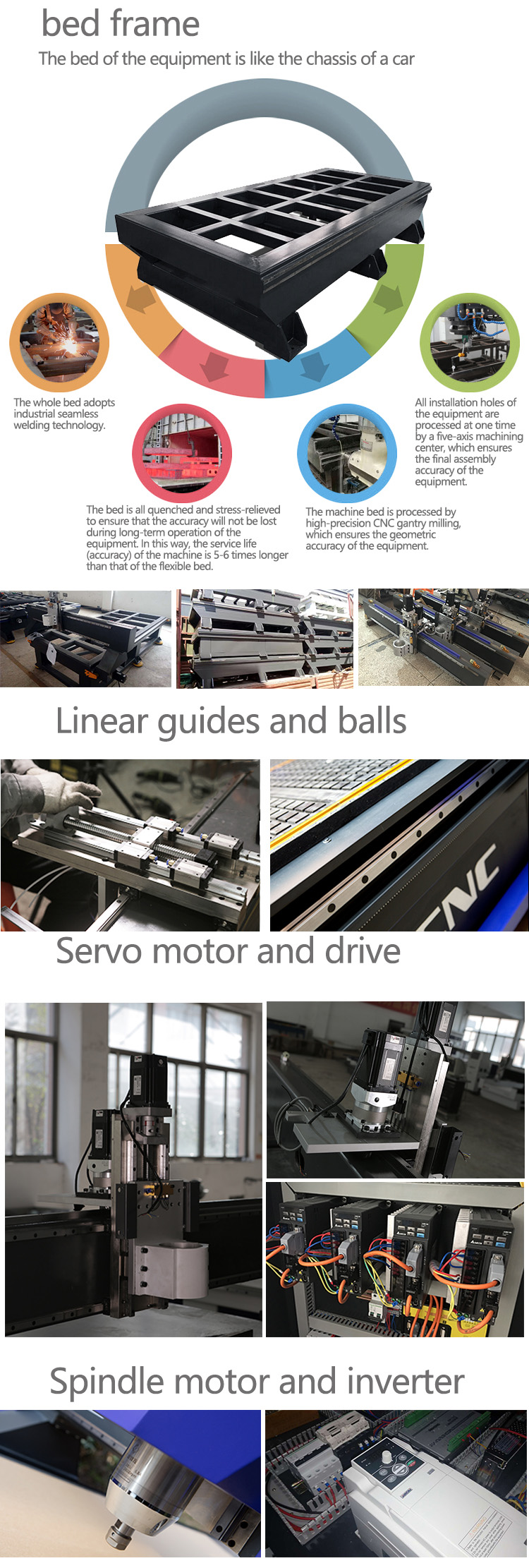

1. Adopt T-style body structure and crossbeam transmission design, main body with Industrial welding technology, quench dealing method and then with high precision milling maching to build. All the accessories are all made one time by 5 axis machining center to ensure machine's rigidity and accuracy.

2. X, Y-axis with imported high-precision rack, Z-axis with imported high-precision grinding grade ball screw.

3. Spindle with high speed, high precision, constant torque, low beating, strong stability, long lifetime characteristics.

4.Supporting G code and PLT code format generated by Type 3, MASTERCAM, CASMATE, Artcam, AUTOCAD, UG, CorelDraw and other CAD / CAM software.