Overview

Condition: New

Range of Spindle Speed(r.p.m): 1 - 30000 rpm

Positioning Accuracy (mm): 0.01 mm

Number of Axes: 3

No. of Spindles: Single

Working Table Size(mm): 1300*1300

Machine Type: CNC Router

Travel (X Axis)(mm): 1300 mm

Travel (Y Axis)(mm): 1300 mm

Repeatability (X/Y/Z) (mm): 0.01 mm

Spindle Motor Power(kW): 7.5kw

CNC or Not: CNC

Place of Origin: Zhejiang, China

Brand Name: GXUCNC

Voltage: 380V/50HZ

Power (kW): 10

Weight (KG): 3500

Control System Brand: NC Studio

Warranty: 2 years

Key Selling Points: High Rigidity

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Printing Shops, Construction works , Energy & Mining, Other, Advertising Company

Machinery Test Report: Provided

Video outgoing-inspection: Provided

Warranty of core components: 2 years

Core Components: Motor

Name: Engraving machine

Working area: 1300x1300mm

Spindle speed: 0-30000rpm/min

Processing speed: 10m/min

Empty travel speed: 18m/min

Processing area: 1300x1300mm

Transmission mode: TBI

Control system: NK300

Vacuum negative pressure pump: 2.2kw

Product Details

|

Working Area |

1300x1300mm |

Repeat position accuracy |

±0.01mm |

|

Total Spindle Power |

7.5Kw |

Drive motor |

Servor Motor |

|

Processing speed |

10m/min |

Guide rail |

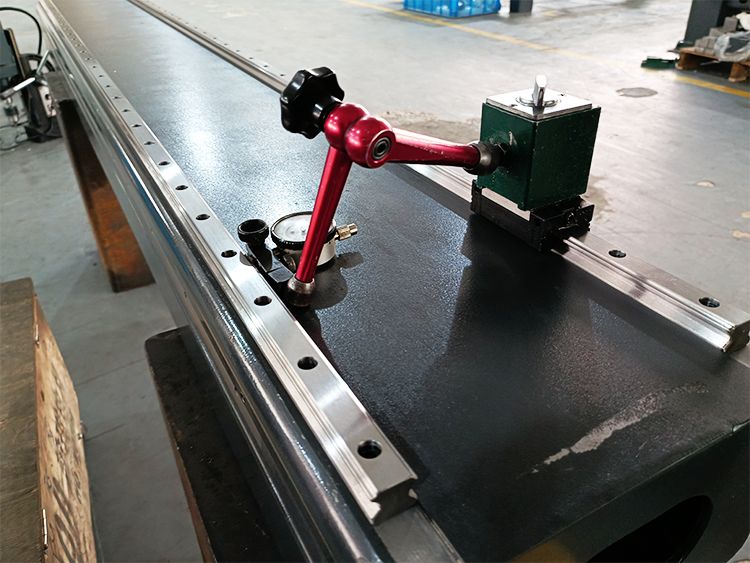

Taiwan high precision guide rail |

|

Processing Accuracy |

±0.01mm |

Transmission mode |

TBI high precision lead screw |

|

Spindle speed |

0-30000rpm/min |

Power supply |

AC380/50Hz |

|

Empty travel speed |

18m/min |

Control System |

WEIHONG NK300 |

|

Vacuum negative pressure pump |

2.2KW |

N.W. |

3500Kg |

Double Lead Screw Automatic Tool Change Engraving Machine

F9-1313 ATC is a new double screw metal processing developed and produced Engraving machine by gxuncc (Guangxu CNC). It mainly uses copper plate relief carving, aluminum door and window carving and other materials. The system supports eng, NC and other formats. The cutting is accurate, convenient and efficient.

Machine Advantage

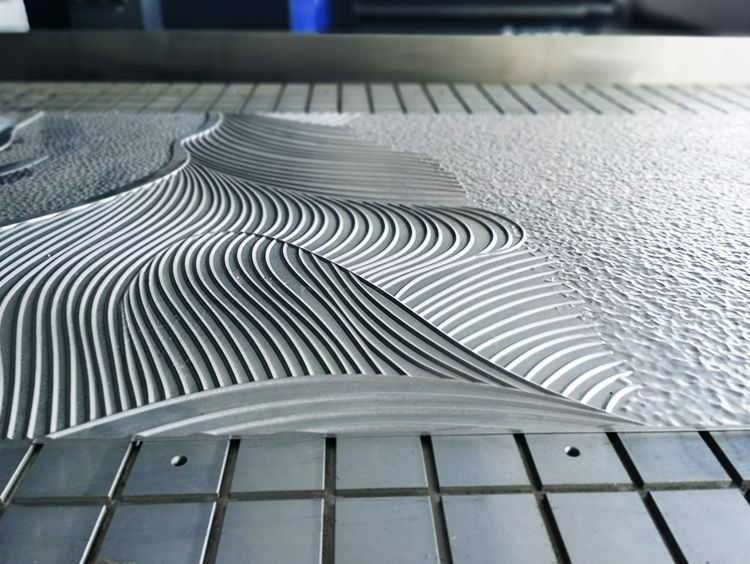

1. This is a high-precision processing equipment, more suitable for a workpiece with more than one tool and high-precision cutting and carving. There is no shadow on the bottom and no vibration on the side of the workpiece.

2. Weihong NK300 industrial control system is a special industrial control system for relief processing, which has faster operation speed;

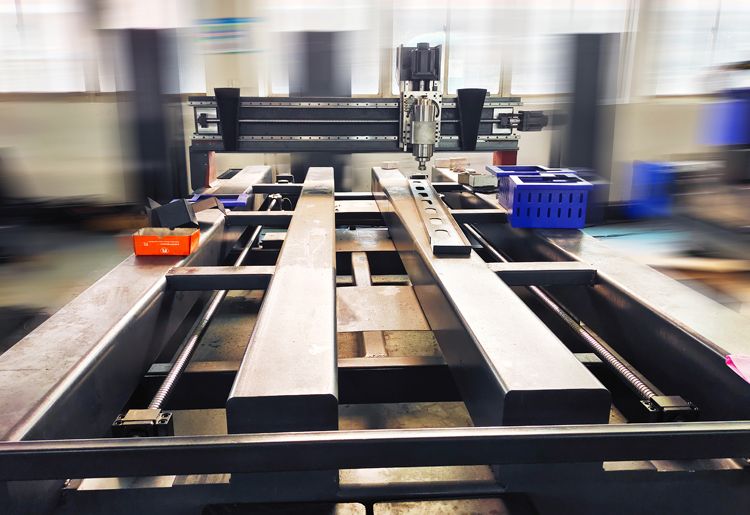

3. The machine weight is 3.5 tons, and the stress is removed by industrial welding tempering to ensure that the bed will not deform for a long time, and the machining precision is more durable and the service life is longer;

4. Imported servo motor, better precision and more stable;aluminum vacuum adsorption table with T-type fixture tooling, to ensure thefirmness of the workpiece to the greatest extent;

5. The 7.5kW high-power tool changing spindle is equipped with 4 tool magazine,which has higher automation and faster efficiency;

6 .Automatic tool change.

Product Display

There is a water circulation system, which can save water resources

The aluminum table is not easy to deform and has high precision

Using WEIHONG NK300 industrial control system.

Stress is removed by industrial welding tempering to ensure that the bed will not deform for a long time.

Metal copper plate relief and aluminum plate door and window carving with high precision.

lubrication system make the machine maintenance easier.

Comes with a dust cover to keep out dust.

The tank chain is divided into compartments, the lines will not be entangled together.

screw very durable ,high precision,large load bearing and stable running.

Equipped with vacuum pump.

Lead screw and guide rail parallelism calibration.

Ail parallelism calibration

Door Show

1.100% quality testing, that is, each machine has been tested strictly in mechanical assembling and performing before delivery;

2.100% sample testing, that is, each machine has been tested by the processed sample before delivery;